ISO 9001 Certified

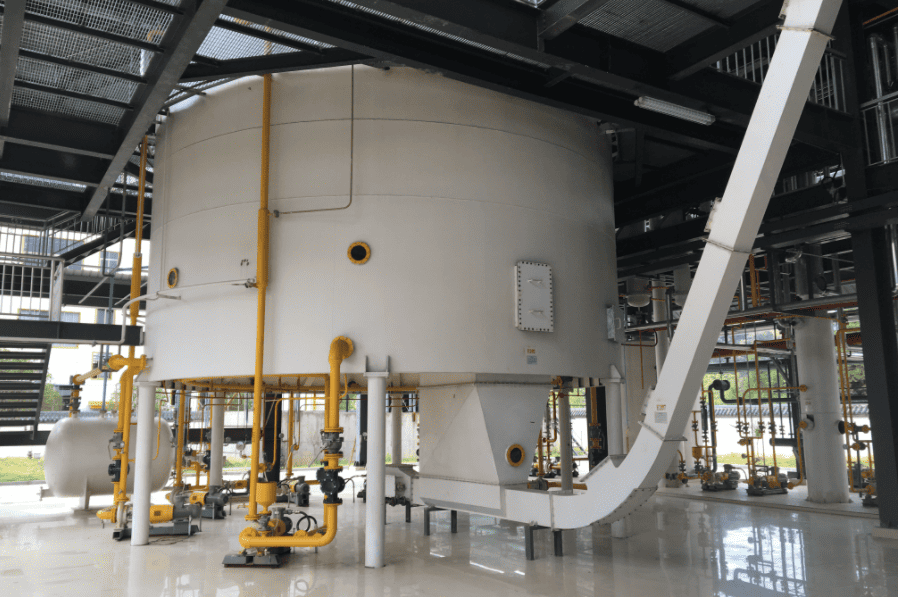

Rotocel Extractor Description

Rotocel extractor adopts rack gear driven,unique rotor balance design, lower rotation speed,small installed power, stable operation without noise, low maintenance cost.

The feeding system adjust the air lock and principal machine rotation speed automatically according to the feeding quantity,keep the certain material level constantly in the material storage tank, in favour of forming micro pressure in the extractor,reduce the hexane leakage; the advanced miscella oil recycling design,in favour of reducing fresh hexane input quantity, reduce the oil residue in the meal, inprove the miscella oil concentration,achieves energy-saving by reducing evaporation capacity; its high material level grid plate design is good for immersion extraction and lowering the meal powder content in the miscella oil, benefit for improve crude oil quality and reducing evaporation system scaling, suitable for each kind of pre-pressed cake extraction.

Adopts SS304 concentric circles to fix the grate bottom, increase the crosswise grid plate, prevent strong miscella oil flow backwards effectively. The extractor adopts auto control feeding, keep regular feeding. The material runs one circle in the extractor, pass through the miscella oil with concentration gradient then spray reversely、fresh solvent spray, after strain off then conveyed to wet meal scraper continuously through extractor unloading device(Adopts material riffling method, reduce the wet meal scraper shocking while unloading,keep it scraping evenly,solve“cross-link”and wet meal system working condition,prolong the scraper lifetime). the extractor adopts gear rack driven,stable operation,small power consumption. It sets air lock at the scraper material falling nozzle on the top of material storage bin, prevent the solvent gas leakage.

Benefit Working With FY Extractio

With a track record of successfully delivering turnkey projects for both large industrial oil plants and small scale oil mill, we have the expertise needed to design and implement the right solution for your edible oil production needs and budget.

The Differences

Project experience across countries and regions

The grease projects undertook cover more than ten provinces and cities including Shandong, Fujian, Shanxi, Xinjiang and Heilongjiang, and the complete sets of equipment were exported to Southeast Asian countries such as Myanmar and Thailand, and the general contracting of engineering technology was completed.

Exclusive Patented Technology

As a result of its patented technologies in New technologies for energy saving and environmental protection, and Intelligent factory automation control, FY Extractio has achieved remarkable results.

Through our work, China’s rice bran oil and woody premium grade oil have made great progress, and we have helped the company build a good reputation and accumulate a lot of strength in the industry.

Cooperation With University

With long-term cooperation with Henan University of Technology, FY Extractio has great engineering design and research capabilities, complete scientific research, design, office hardware, and advanced computer design software;

Work During Chinese New Year

We will be available even during Chinese New Year to provide you with the fastest response possible.We are available for meetings, emails, messaging any time during your working day.