ISO 9001 Certified

oil extraction machine Manufacturing

FY Extractio is a leading manufacturer of high-quality oil extraction machines for the oil manufacturing industry. Our durable and reliable machines are designed for use in oil mills and other production facilities, providing efficient and effective solutions for all your oil extraction needs. Trust us to deliver the high-quality equipment you need to succeed in the competitive oil manufacturing industry.

Send An Inquiry Now

One Stop Seed Oil Extraction Machine Manufacturer

FY Extractio is your one-stop supplier for all your seed oil extraction machine needs. As a leading manufacturer of high-quality oil extraction machines, we offer a range of automatic machines designed to meet the needs of the edible oil production industry. Our machines are designed to operate smoothly and deliver consistent, high-quality cooking oil. Trust us to provide the reliable and efficient solutions you need to streamline your seed oil extraction process.

At FY Extractio, we are committed to delivering high-quality seed oil extraction machines that meet the needs of our customers. Whether you’re producing cooking oil or other types of oil, our machines are designed to deliver optimal performance and consistent results. With our comprehensive installation and technical services, you can trust us to provide the support you need to keep your operation running smoothly. Contact us today to learn more about our machines and how we can help you achieve your production goals.

Explore Our oil extraction machine Categories

Explore the specific card below to view the targeted machines.

Heat Exchanger

Heat exchange is high effective energy-saving equipment, suitable for multiple medium heat exchanging(Water-Oil/Oil-Oil/Miscella oil-Steam),high heat transfer coefficient, realize the secondary… ...

Desorption And Absorption Tower

Desorption And Absorption tower are key equipments in the tail gas recovery process, equipped cooperatively with absorption tower、cool oil pump、cooler、heat… ...

Miscella Oil Filter

Miscella oil filter is a kind of equipment make filtration for miscella oil from extraction. After filtration, reduces the meal… ...

Stripper

The stripper is typically used to remove the last traces of solvent that may be present in the oil, which… ...

Evaporator

An evaporator is a type of equipment used in the oilseed processing industry for solvent recovery during oilseed extraction. It… ...

Wet Trapper

Wet trapper is a kind of equipment which separates the gas with solid particles in the Chemistry,Food industry,etc; belongs to… ...

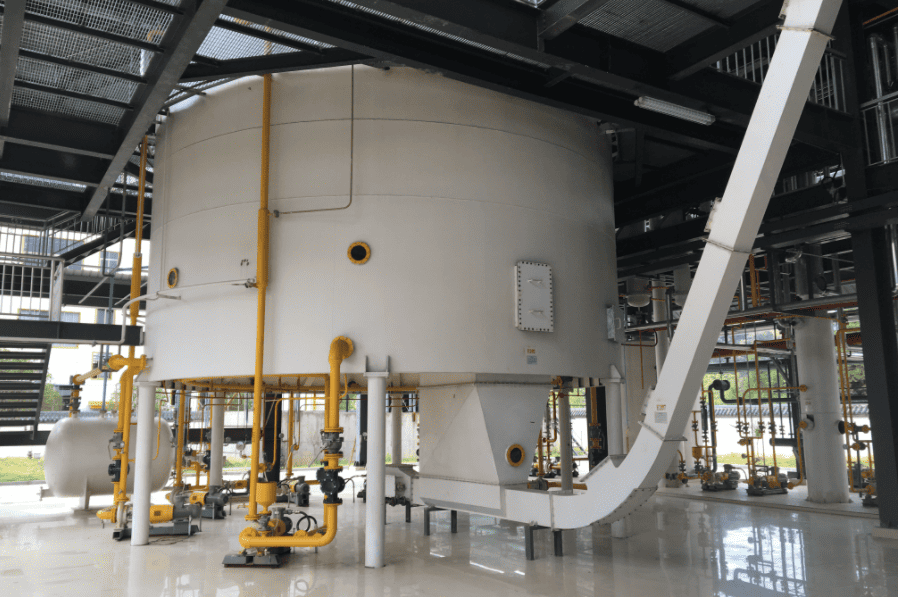

Desolventizer

DTDC series of desolventizer is the best choice for wet meal desolventization, it can finish the desolventization and drying for… ...

Rotocel Extractor

Rotocel extractor is used in the oilseed processing industry for solvent extraction of oil from oilseed materials. It is a… ...

Towline Extractor

The towline extractor is a type of equipment used in the oilseed processing industry for solvent extraction of oil from… ...

What are oil press machine , screw oil press and oil expeller? And differences.

Oil press machines, screw oil presses, and oil expellers are all mechanical devices used in the edible oil processing industry for the extraction of oil from different materials such as seeds, nuts, and fruits.

Oil press machines use mechanical pressure to extract oil from the source material. The machine typically consists of a horizontal cage with a shaft that rotates to crush and press the material, forcing the oil to flow out. Oil press machines are often used for producing crude oil from sources such as castor beans.

Screw oil presses, on the other hand, are designed to press oilseeds with a high oil content. The machine typically uses worm shaft to apply pressure to the oilseeds, forcing the oil to flow out. It can produce higher oil yields than oil press machines and are often used for producing oil from sources such as peanuts and soybeans.

Oil expellers are another type of oil extraction device that uses a screw shaft to press oilseeds and extract oil. However, oil expellers are designed to operate at a higher temperature than screw oil presses, which can result in a higher oil yield. They are often used for producing oil from sources such as sunflower seeds and cottonseeds.

Overall, oil press machines, screw oil presses, and oil expellers are all great ways to extract oil from different materials. The choice of machine will depend on the specific needs and preferences of the user, as each machine has its own unique advantages and disadvantages. In addition to mechanical extraction, other methods such as solvent extraction and oil refining may also be used to extract oil from various sources. The production capacity of these machines can vary from a few kilograms to several hundred tons per day, and they are often used in the export market to provide high-quality, high-oil yield crude oil.

What oilseeds that can apply to solvent extraction?

Solvent extraction is a widely-used method for extracting oil from oilseeds that have a low oil content or require a more efficient extraction process. There are several different oilseeds that can be processed using solvent extraction, and they are commonly used in the production of edible oils.

Soybean is a popular oilseed that is processed using solvent extraction and produces high-quality oil that is commonly used in cooking and as an ingredient in various food products. Peanut oil is another widely-used oil that is extracted using solvent extraction and is commonly used in cooking, as well as in the production of margarine and other food products.

Sunflower oil is extracted using solvent extraction and is commonly used in cooking, as well as in the production of salad dressings and margarine. Rapeseed and canola are also oilseeds that are commonly processed using solvent extraction and are used for cooking and in the production of biodiesel.

Coconut oil is another popular oil that is extracted using solvent extraction and is commonly used in cooking and as an ingredient in many food products, including baked goods and snacks. Palm kernel oil and palm oil are also extracted using solvent extraction and are widely used in cooking and food production.

Other oilseeds that undergo solvent extraction include rice bran, castor seed, and corn germ. These oils are used in various applications, such as the production of margarine, soaps, cosmetics, and lubricants.

Overall, solvent extraction is an important process in the edible oil industry, allowing for the extraction of high-quality oil from a variety of oilseeds.

Solvent Extraction Machinery Glossary

underground solvent tank

Tank installed underground for solvent storage. Generally, it is a steel horizontal cylindrical tank with the liquid level at least 0.2 m below the nearby ground elevation, and is required to be more than 6 m from the workshop.

half-underground solvent tank

Part of the tank body in the surrounding ground below the solvent storage tank, generally for the steel horizontal cylindrical tank body. Its safety level is slightly worse than underground type, so the distance between it and extraction plant is required to be 8 m.

extractor

Collective name for the equipment used to complete the extraction process of oils and fats.

rotocel extractor

The equipment that rotates with the vertical axis to complete the whole extracting process of loading, extracting, dripping and draining.

seal auger

A horizontal closed screw conveyor with a small section of rotor blade missing at the discharge end and a gravity door. It is the feeding mechanism of the extraction auger.

extractor shell

The extractor shell supports the weight of the rotating body. It is a shell that is mounted on the guide rail of the rotor and is equipped with an oil collection compartment and a meal outlet compartment in the lower part, and plays a role in sealing the solvent in production.

rotor

A cylinder divided into several extraction cells along the radial direction and rotates slowly with the vertical axis.

cell

The cell that carries the oil for extraction in the rotating body of the flat rotating leaching machine.

false bottom

The bottom of the extraction cell is composed of a screen and a sieve plate, which can be disconnected to complete the unloading operation.

sprayer/spray nozzle

A device that sprays solvent or oil mixture onto the stock.

miscella funnel/miscella collection chamber

A hopper that collects mixed oil or solvent under the rotating body.

meal discharge cell/meal collection chamber/meal hopper

A cell for collecting wet meal after extraction is completed.

rich miscella screen filter

A screen panel shaped like a tent, installed at the top of the rich miscella discharge hopper, which filters the extracted rich miscella to remove the meal.

front opening door

This is a device that moves with the rollers of the false bottom in the front and the hinged shaft in the back when unloading the meal.

Back opening door

When unloading the meal, the hinge of the false bottom is in the front and the roller is in the back in the form of dragging.

feeding stage

The stage when the material enters the extraction vessel until it is leached.

extracting stage

The stage when the material is extracted in the extraction vessel.

draining stage

The stage when the solvent in the meal is finally drained after spraying.

bridging

Also known as “arching”. In the container, the material blanks are bonded to each other and squeezed, so that the flow stops, resulting in the phenomenon of the lower part of the container hollow.

Screen belt type solvent extractor

The equipment that moves the billet horizontally on the screen belt to complete the continuous leaching process.

fixed cell extracotor

The extraction cell is fixed, while the feed pipe, spray pipe, meal outlet and mixing hopper rotate in the opposite direction of the corresponding action of the flat rotation leachers.

loop type extractor

This is a continuous extraction machine in which the loop-shaped billet is dragged by a frame type drag chain conveyor.

batch extractor

A closed vessel with a stirring device and a false bottom inside, capable of intermittent extraction, usually used in groups.

miscella circulating pump

A pump used to circulate the oil mixture in the extraction process.

solvent pre-heater

A device for heating the solvent to the required temperature before leaching.

solvent holding tank

A container for storing the solvent recovered from each system for recycling in the extractor.

miscella tank

A container for storing mixed oil and settling its meal.

miscella filter

A device that removes the meal from the oil mixture through a screen.

liquid-cyclone

A device that removes the meal from the oil mixture by centrifugal separation.

raising film evaporator

Also called “raising film evaporator”. Equipment that evaporates mixed oil in an upright long tube in the form of a thin film.

constant level tank

A vessel to adjust the level of oil mixture in a long tube evaporator.

vopor separator/miscella separator

Also called “flash tank”. Used in conjunction with the long tube evaporator. After the mixed oil is evaporated by the rising film, it enters the separator, the solvent is flashed, and the liquid is separated from the vapor under the action of centrifugal force.

tubular stripping column

The equipment that removes the mixed oil solvent from the tube by direct steam.

disk stripping column

Vapor stripping equipment that uses a disk set as a contact surface for water vapor and concentrated oil mixture.

plate steam stripping tower

A steam stripping equipment that uses a sloping plate as a contact surface for water vapor and oil mixture. It is a steam stripping tower with alternating inclined plates in a rectangular housing.

filling steam stripping tower

It is a steam stripping equipment that increases the contact area between water vapor and oil mixture by using filler in the tower. The filling tower is mainly composed of the tower top, tower body and tower base.

meal storehouse

Storage or turnover meal storehouse. Generally for single-story room type warehouse. Some meal storehouse also has the function of measuring, packing. According to the fire code meal storehouse electrical equipment, should be explosion-proof type to ensure safety.

meal cooler

The meal cooler is the equipment that cools the meal after the high temperature of desolvation and steaming. This machine is often used for cooling soybean meal.

desolventizer-toaster

A machine with a cylindrical body and a stirring device that removes solvent and water from wet meal with direct steam and indirect steam.

Horizontal desolventizer-toaster

A steam dryer installed by overlapping a number of horizontal cylinders.

vertical desolventizer-toaster

Also known as “layer desolventizer”, it is a desolventizer installed by overlapping a number of pots and pans.

DT desolventizer-toaster

A desolventizer-toaster consisting of several pots and pans mounted on top of each other and having the function of baking meal.

desolventizer-toaster with integrated dryer-cooler

Layer-type steamer-toaster with cooling effect on meal.

automatic flow controlling gate

A device that controls the level of the material in the layer or the upper layer by the level itself.

high bed desolventizer toaster

Only one or two layers of cylinder, thick layer of material, with stirring device to use steam to remove the solvent in the wet meal steam stripper.

wet fines catcher

Using the method of spraying water or solvent to remove the meal caught in the solvent steam equipment.

dry fines catcher

The equipment that separates the meal caught in the solvent vapor by using the principle of centrifugal sedimentation.

flash desolventizing system

Spraying wet meal with superheated solvent steam in the evaporation pipe to evaporate the solvent out of the meal in suspension.

soybean meal low temperature desolventizer

The equipment for low temperature desolventizing of wet soybean meal under atmospheric pressure. Mainly composed of spiral scraper desolventizer, circulating fan, cyclone separator, solvent steam superheater, meal settler, closed valve, etc.

Horizontal low temperature desolventizer

Also called A, B cylinder desolventizer. It is a low temperature desolventizer installed by two horizontal cylinders overlapping each other. It is mainly composed of spiral scraper desolver, circulating fan, cyclone separator, solvent steam superheater, meal settler, closure valve, meal outlet, etc.

pipe bundle condenser

This equipment is equipped with many parallel tubes forming a pipe bundle in a cylindrical shell to condense solvent vapor through heat exchange. There are horizontal and vertical types.

Spraying condenser

The equipment that condenses solvent vapor in the discharge pipe by spraying with water.

Contact condenser

A device that cools solvent vapor by direct contact between cooling water and solvent vapor.

atmospheric condenser

The equipment that condenses solvent vapor by using air, and water can be used as coolant.

balancing tank

A vessel that allows the free gas in each equipment in the extraction plant to collect and balance the system pressure.

solvent separator/water separator

The equipment that separates solvent and water by taking advantage of the difference in specific gravity between the two.

waste-water boilling tank

A device that heats and boils the wastewater discharged from a water separator to recover the solvent.

Freezing recovery device

A device that recovers solvent by lowering the exhaust gas to about 0°C.

vent gas condenser

A device for recovering solvent by cooling the exhaust gas with cooling water.

mineral oil absorbing device

A device that absorbs solvent vapor in the exhaust gas with mineral oil, mainly consisting of an absorption tower, heat exchanger, desorption tower, cooler, etc.

Packing absorbing column

Solvent recovery equipment that uses packing in the column to increase the contact area between absorbent, vegetable oil or mineral oil and exhaust gas.

desorption column

The equipment that removes solvent from rich oil by direct steam.

Water seal tank

A facility that prevents solvents from entering the sewer.

fire barrier

A safety device for fire protection.

Your go to supplier and exporter for oil extraction

FY Extractio is a reliable supplier and exporter of oil extraction equipment. Our mechanical oil pressing machines are designed for use in production lines, providing durable and efficient means of extracting crude and vegetable oil. With comprehensive installation services and high-quality machinery, we offer the support needed for successful oil extraction operations. Contact us today to learn more about our leading solutions and start your oil extraction process with confidence.